TEA BAGS

Non-woven triangular tea bag processing

The non-woven packaging material is a filter type of bag that can contain fined tea leaves.

The non-woven bag that can drain water depend on different raw material.

Even though the filling inside is difficult to see, various forms of raw materials can be added.

We can produce both bags with tag or without tag, so please choose according to your purpose.

Related Products

-

Triangular Tea Bag Processing

The triangular bag is the most popular type of teabag. Since there are many types of materials, we will make proposals according to the raw materials.

-

Kawaiipack Seasonal Product For [New Year]

The [kawaiipack] product line is manufactured according to the OEM processing method with a special technique. Various sizes and shapes can make into a funny or gorgeous teabag such as cute and goofy characters, cute animals, floral shapes, fashion, messages, and some shapes according to a particular season.

-

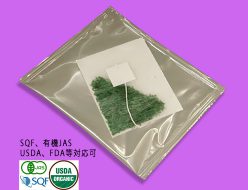

Individually Wrapped Triangular Teabag Processing

In recent years, the demand for individually wrapped triangular tea bags has been rapidly increased. To ensure long-term preservation, each package is individually wrapped and filled with nitrogen.

-

Individual packaging teabag manufacturing

By using individual wrapping film, individually package OEM for triangular tea bags, drip coffee bags, and drip tea bags are available.

-

Seasonal Product “kawaiipack” For Halloween

The teabag with special designs product line-ups "kawaiipack" with OEM processing method is a type of teabag product that attract younger generations recently. The main reason is various shapes can make into teabags that suit the aesthetic taste of the youth such as funny characters, cute animals, flowers, etc (please check the following website for more information: https://kawaiipack.wela.jp/).

-

Individually Wrapped Flat Tea Bag Manufacturing

The common flat tea bag is still one of our important products. Each wrapped tea bag is filled with nitrogen afterward to ensure long-term high quality. We used highly advanced technology to suppress each tea bag's oxygen residue rate below 3%.

![[Improving the efficiency of pharmacy operations] Making manufacturing records online (with easy steps) [Improving the efficiency of pharmacy operations] Making manufacturing records online (with easy steps)](/wp-content/uploads/2018/03/kusuri_580px_380px-200x200.jpg)

![[Cosmetic Production] Offering Wide Range Of Support From Small Amount Filling For Sample Product, To High Degree Difficulty Of Filling Process [Cosmetic Production] Offering Wide Range Of Support From Small Amount Filling For Sample Product, To High Degree Difficulty Of Filling Process](/wp-content/uploads/2021/11/22147373_s-200x200.jpg)

![[Renewal] Whole Catechin Powder Stick Pack Green Color [Renewal] Whole Catechin Powder Stick Pack Green Color](/wp-content/uploads/2022/04/new_marugoto_green-1-200x200.jpg)

![[Example Cases] Related To WordPress [Example Cases] Related To WordPress](/wp-content/uploads/2019/04/wp_0907_R-200x200.jpg)